Helix Water District Upgrades Water Treatment, Saves Costs

A recent upgrade to a Helix Water District treatment plant saved money for its ratepayers while ensuring a continued supply of high quality drinking water.

After 20 years of service, the ozone disinfection system at the R.M. Levy Water Treatment Plant needed an upgrade. The projected cost of outsourcing the work needed came to $3.5 million. Instead, Helix staff at the plant proposed doing the work themselves – and they did – saving an estimated 70% after the work was completed for $1.1 million.

“With infrastructure projects, we always start with two questions,” said Helix Water District General Manager Brian Olney. “Do we replace it or can we rehabilitate it? And, is it better to outsource the work or do it in-house? These two questions saved our customers millions of dollars this year and are a good example of how we continuously look for ways to save our customers money.”

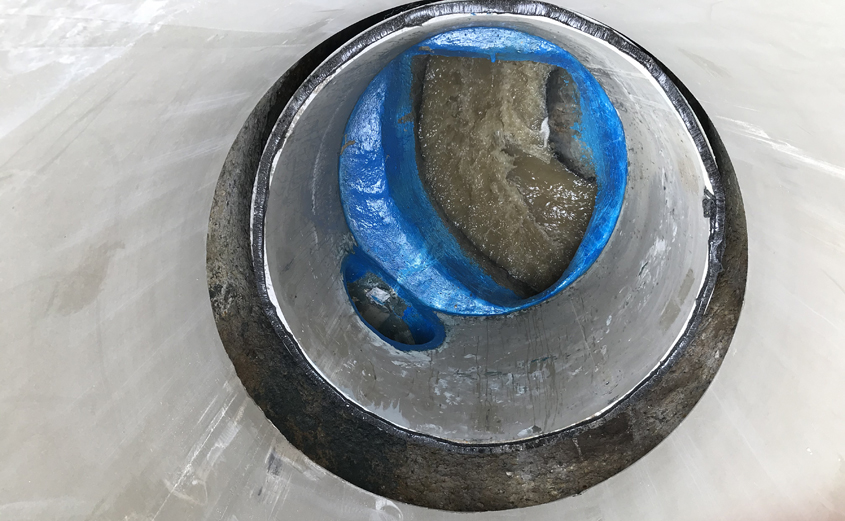

The Helix Water District uses ozone generators to reduce the use of chlorine as a primary disinfectant. Ozone inactivates a wide range of microorganisms, needs little contact time with the water, and it eliminates most of the odor and taste issues some people associate with tap water. Photo: Helix Water District

Ozone Disinfection and Drinking Water

Water treatment is a multi-step process. First, organic material suspended in the water is removed. Water is then disinfected to remove or inactivate harmful microscopic organisms. Finally, the water is filtered.

Chlorine is the most widely used disinfectant at conventional water treatment plants. The Helix Water District uses ozone as its primary disinfectant, supplemented with chlorine. Ozone inactivates a wide range of microorganisms, needs little contact time with the water, and it eliminates most of the odor and taste issues some people associate with tap water. This mix maintains the quality of the water while it makes its way through the water distribution system.

The treatment plant uses an ozone generator, which produces ozone by applying high amounts of electricity to oxygen gas. The oxygen molecules (O2) split and regroup as ozone (O3). The ozone gas then bubbles up through the water to inactivate any microorganisms present.

Upgrading ozone generators with new technology

Helix maintenance staff worked closely with the manufacturer of its original ozone system installed in 2002. The same manufacturer supplied new hardware and electrical components required for the upgrade. The ozone disinfection system includes the gas feed systems, generators, power supply units, and the instrumentation hardware and software controlling the system.

The project began with a proof-of-concept pilot project two years ago. Once the methods were tested, each of the three ozone generators was upgraded with the new technology, then tested and commissioned.

In addition to the 70% estimated cost savings from the upgrade project, the improved efficiencies of the ozone generators will produce long-term cost savings.

The ozone generators and their power supply units are now fully upgraded thanks to the efforts of the Helix team. The last phase of the project is the replacement of the computer control system, which is scheduled for 2024.

(Editor’s Note: The Helix Water District is one of the San Diego County Water Authority’s 24 member agencies that deliver water across the San Diego region.)